Semi-automatic Nursery Seed Sowing Machine For Vegetable Growing

The semi-automatic manual type nursery seed sowing machines are suitable for cavity seeding of a wide range of vegetables, flowers, and herbs, and are widely used in greenhouses, small farms, and home gardening.

The semi-automatic manual type nursery seed sowing machine is an efficient seeding tool designed for small and medium-sized vegetable, fruit, melon, and flower planting. It is easy to operate and compact, suitable for greenhouses, small farms, and home growers.

By manually controlling the sowing rhythm and position, the device can accurately sow seeds into the seedling hole tray. This effectively improves sowing efficiency and seeding neatness, helping growers to significantly save labor and time, and is an indispensable assistant for a modern and efficient seedling nursery.

Application scope of nursery tray seedling machine

This nursery seed sowing machine is suitable for a wide range of seed types and shapes, including but not limited to:

- Vegetables: tomatoes, peppers, lettuce, cucumbers, kale, broccoli, celery, etc.

- Flowers: all types of round or tiny flower seeds.

- Herbs: mint, basil, parsnips, and other types of herbs.

Whether it is home balcony planting, or greenhouse batch seedling, just tell us the type of seed you use, we can provide sowing test to show the real sowing effect.

Hand-operated nursery seeder machine features

- Easy to operate: manually control the sowing rhythm, more flexible and easy for users to get started.

- Precise sowing: can accurately control the sowing depth and spacing to ensure neat and consistent seedlings.

- Strong adaptability: compatible with a variety of specifications of the hole tray and seed shape, without frequent replacement of accessories.

- Cost saving: save labor and seeds, especially suitable for small batch and multi-species sowing needs.

- Portable: lightweight body, suitable for flexible use in a variety of environments.

- Stable and durable: simple structure, low maintenance and long service life.

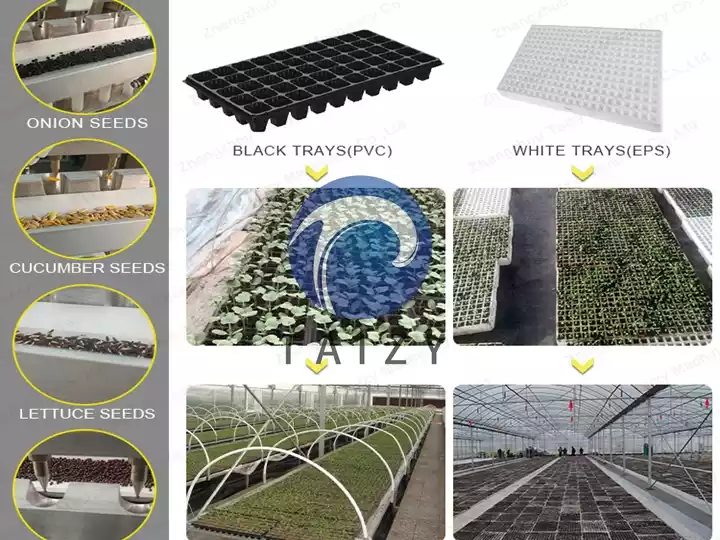

Applicable seeds display

Some of the seeds are listed below, as well as some smaller and irregularly shaped seeds that are pill-coated to make it easier to suck the seeds.

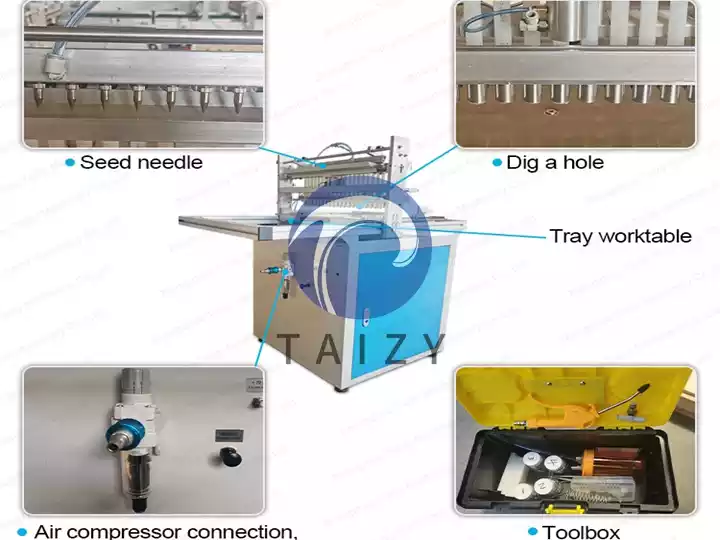

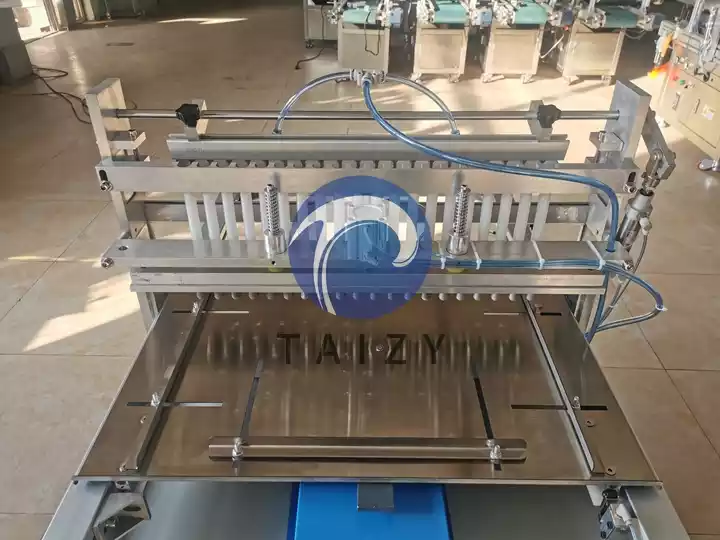

Vegetable seed planting machine structure

The structural composition of this nursery seed sowing machine is relatively simple and consists of a tray worktable, seed needles, seed drop tubes, a punching section, a toolbox(a set including five kinds of suction needles from No.1 to No.5), and also an air compressor.

Depending on the size of the trays and the number of holes you need, we can customize this nursery seed sowing machine.

How to use a manual nursery seed sowing machine?

Preparation

- Ensure that the nursery machine and seed and cultivation trays are cleaned and sterilized as necessary.

- Select healthy, disease, and pest-free seeds, and choose appropriate seed holes according to the size of the seedling tray.

Operating procedure

- Adjusting seeding depth: adjust the seeding depth of the nursery according to the size and requirements of the seeds to ensure that the seeds are properly buried in the soil.

- Filling the seed: place the seed evenly into the seed bin of the seedling dispenser.

- Putting in substrate soil: manually put the nutrient soil into the hole tray, and then put the tray into the machine, which has a sensor switch that senses the hole tray for automatic punching.

- Seeding: aim the seedling machine at the seedling trays and start the operation according to the required spacing and number of rows to make sure the seeds fall into each hole evenly.

- Compacting the soil: use your hands or special tools to gently compact the soil after sowing to ensure that the seeds are in full contact with the soil.

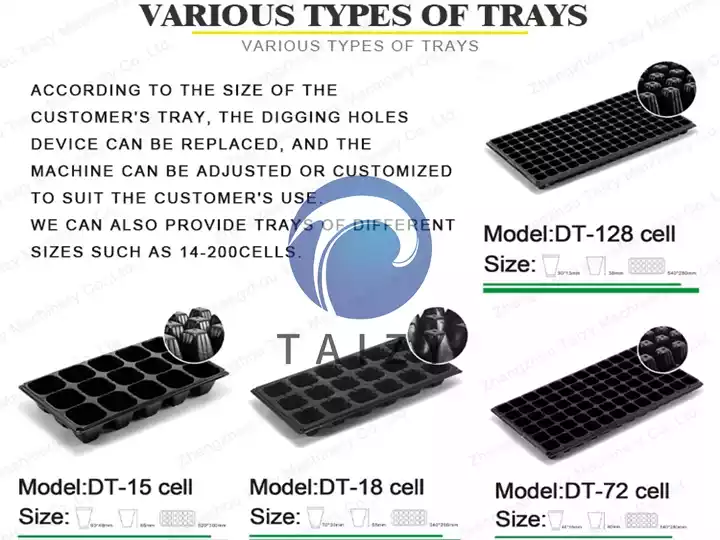

Nursery seeding tray details

Depending on your needs, we can provide different burrowing trays. The black standard burrow tray size is 540x280mm, and the common hole number is usually 32, 50, 72, 105, 128, 200, etc. The white floating tray can be customized according to the customer’s demand.

Nursery seeding machine technical parameters

| The material of the nozzle | KMR-78 |

| Capacity | 200trays/h |

| Size | 1050*650*1150mm |

| Weight | 68kg |

| Material | carbon steel |

| Material of the nozzle | Aluminum alloy |

Customer feedback machine use effect

We have many years of experience in producing this nursery seed sowing machine. So far, we have exported to more than 20 countries, such as the United States, Australia, Ghana, Kenya, Nigeria, South Africa and some other African regions. The following shows the excellent cultivation results from our customers.

Precautions for using the machine

- Seed selection: choose the right seed size for the nursery seed sowing machine to avoid too small or too large seeds that will lead to uneven sowing.

- Sowing spacing: adjust according to the growth demand of the seeds and the hole spacing of the seedling trays to make sure the seeds have enough space to grow.

- Sowing depth: different seeds have different sowing depth requirements and should be adjusted according to the characteristics of the seeds.

- Maintenance and cleaning: clean the seedling machine regularly to avoid the accumulated impurities affecting the seeding effect.

- Practice and adjustment: when using for the first time, it is recommended to carry out a small-scale test sowing first, and adjust the operation techniques and machine settings according to the actual results.

In addition to the semi-automatic machines shown above, our factory also processes two other fully automatic seedling machines. For details, please click Hot-selling Automatic Nursery Seedling Machine For Farming and PLC-100 Automatic Nursery Tray Seeding Machine For Sale. Feel free to contact us!