PLC-100 Automatic Nursery Tray Seeding Machine For Sale

This article details the functional features of PLC’s new nursery tray seeding machine, demonstrating its ability to provide users with an efficient, accurate and intelligent nursery solution.

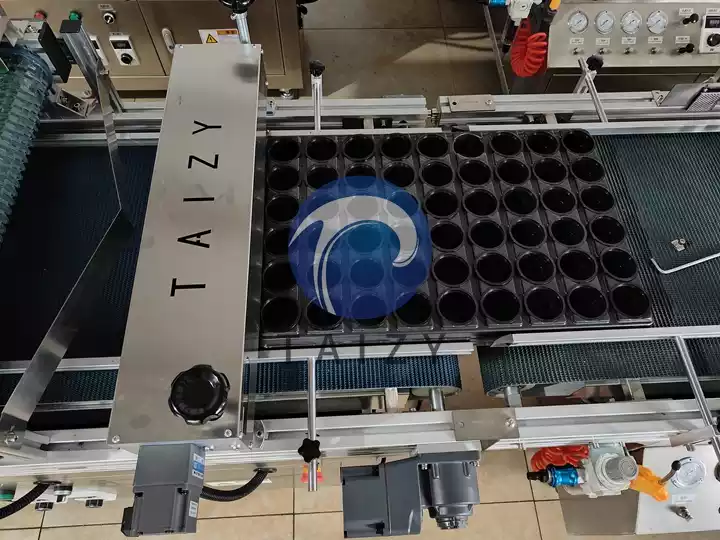

This new automatic nursery tray seeding machine combines advanced technology and efficient functions. Equipped with a PLC system, the machine is capable of precise seed positioning, automatic seeding, mulching, irrigation, and environmental control, greatly improving planting consistency and success, and can be widely used in large agricultural plantations.

The nursery tray seeding machine uses a PLC system instead of the KMR-78-2 model’s circuit board and is suitable for use with highly complex, customized black hole trays as well as white floating trays. Notably, a suction needle with three tips allows three seeds to be sucked at a time while allowing for staggered seed drop.

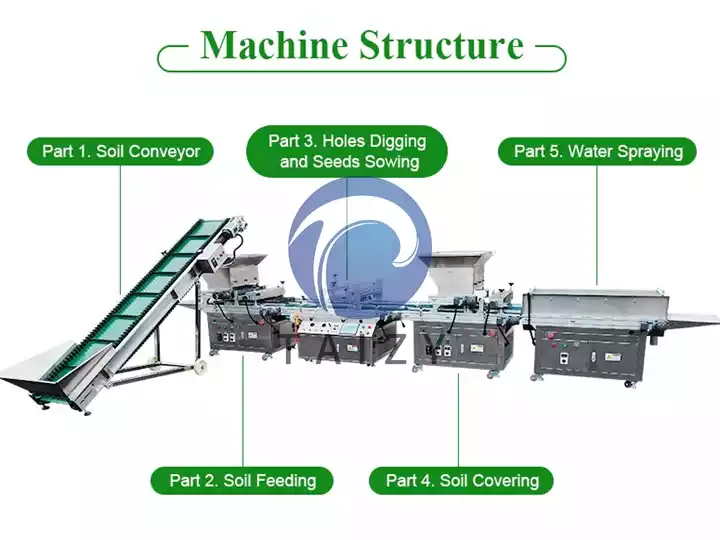

Machines with soil lifting function

Equipped with an optional lifting top soil device, this feature automatically adds soil or culture media precisely to the seeding hole, ensuring that the seed is properly covered and improving seeding success.

Machines with water sprinkling function

This nursery tray seeding machine has an optional sprinkler function that automatically provides the right amount of water to the seeding area to keep the soil moist and promote seed germination, providing growers with a convenient and efficient irrigation solution.

Full automatic vegetable seedling machine specifications

| Model | KMR-100 | KMR-100 with watering part |

| Capacity | 500-1200trays/hour (the speed of the tray can be adjusted) | |

| Precision | >97-98% | |

| Principle | Electrical and air compressor | |

| System | Automatic photoelectric sensor detection PLC system | |

| Material | Stainless steel | |

| Power | 650w | |

| Size for seed | 0.3-15mm | |

| Tray size | Normal standard is 540*280mm | |

| Size | 4800*950*1600mm | 5600*950*1600mm |

| Weight | 400kg | 540kg |

Some tips for PLC-100 nursery tray seeding machine

- White has to learn every time.

- You have to go through it again before each use, and the program will be lost after a power outage.

- The black tray has no gap at the bottom and cannot be planted in double rows.

- PLC replaces the circuit board.

- The black plate can drop seeds in double rows, since the bottom, and can also work in alternate rows.

- White disks cannot be double-rowed and cannot be sensed, so they need to be set up.

- Touch screen, white plate sowing settings, re-learning when power is off, not learning – learning is completed.

- The length of the plug tray is detected and the number of transverse holes is set.

- Delay time, partition, planting sooner or later, only the first row needs to be set.

- 3 times the size of the pellets, even large and heavy pellets will not work.

Advantages of nursery tray planting machine

- The plug seedling technology has the advantages of saving labor, saving energy, facilitating large-scale management, and protecting and improving the agricultural ecological environment. Therefore, it is widely used in vegetable and flower production.

- The nursery tray seeding machines have a high germination rate and strong seedling vitality. This saves seeds significantly.

- The substrate used is mainly peat soil, vermiculite, perlite, etc., with light specific gravity, good air permeability and water retention, moderate pH, and low virus contamination.

- The substrate does not adhere to the plug surface and comes out of the tray easily. It does not adhere to the surface of mechanical parts, making it convenient for mechanical operation.

- The density of plug seedlings is several times higher than that of traditional seedlings. Therefore, the fixed investment cost of the greenhouse is amortized on a per-seedling basis. And the greenhouse operating expenses are also greatly reduced.

- Using the seeder assembly line can make the filling amount, sowing depth, compaction degree, and coverage depth of each hole of the plug consistent. Moreover, the emergence date and size of the seedlings are uniform, which is conducive to the commercialization of the seedlings.

- Using stainless steel, we can easily sterilize the entire plug seedling production line.

Principles to be followed in selecting machines

- When using plug seedling technology, how to choose a nursery tray seeding machine is related to the cost of seedlings and the quality of the seedlings.

- Consider it from the perspective of ecological and environmental protection. It requires the absence of viable pathogens and larvae. And do not contain or try to avoid containing harmful substances.

- Prevent contamination of the environment and food chain after the seedlings enter the planting area. To achieve this, a starter should be used for rapid fermentation to achieve the purpose of sterilizing, killing viruses, and removing larvae.

Shown below are customer feedback on seedlings based on our recommendations.

Our factory has been specialized in the production, manufacturing, and export of seedling machines for many years. We have different types of machines for you to choose from. For more information, please click Semi-automatic Nursery Seed Sowing Machine For Vegetable Growing and Hot-selling Automatic Nursery Seedling Machine For Farming. We welcome you to visit our factory, please feel free to contact us, and look forward to cooperating with you!