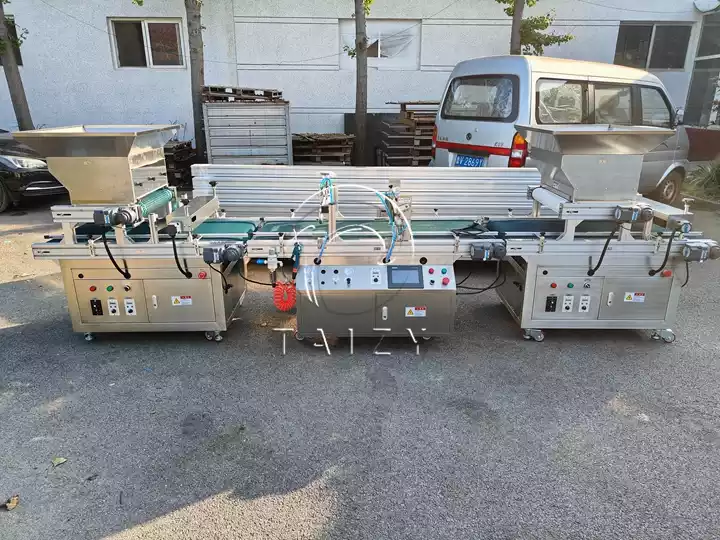

Máquina sembradora automática de vivero PLC enviada a Ucrania

Great news! A batch of PLC-controlled, fully automatic nursery seeder machines (KMR-100) from our factory has completed production, debugging, and inspection. They have been successfully packed and shipped to Ukraine, where they will be deployed in large-scale local seedling nurseries.

Customer background and project overview

The client enterprise primarily serves farms, agricultural cooperatives, and facility agriculture parks in Ukraine and surrounding regions. It specializes in large-scale cultivation of common commercial vegetables such as tomatoes, bell peppers, cucumbers, Chinese cabbage, and kale, acting as a key supplier of commercial seedlings within the local vegetable industry chain.

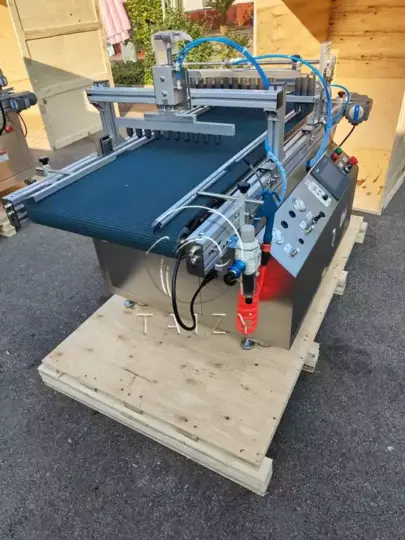

After comprehensive comparisons and technical discussions, the client selected our KMR-100 PLC-controlled automatic nursery seeder machine. This equipment integrates automated hole-digging, seeding, and soil-covering operations for tray seedling production, meeting the client’s primary vegetable and cash crop seedling production requirements.

Core requirements and equipment matching

The client primarily uses standard 600×400mm seedling trays on-site, commonly employing 96-cell and 160-cell trays. Seed particle sizes range from 0.3–12mm, with clear requirements for seedling precision, stability, and automation:

- Stable continuous operation of hole-digging, seeding, and soil covering to minimize manual intervention.

- Maintain seedling production efficiency for large-scale operations with adjustable speed settings.

- Ensure high sowing accuracy to minimize empty cells and skipped seeds, guaranteeing uniform seedling emergence.

- Constructed with stainless steel to meet agricultural hygiene and durability standards.

- Equipped with automatic detection and PLC control systems for simple operation and reliable performance.

Our KMR-100 nursery tray seedling machine configuration and parameters fully address these requirements, adapting to customers’ existing seed trays, seeds, and site conditions.

Details of this automatic nursery seeder machine

- Operations: Hole digging + Seeding + Soil covering

- Capacity: 400–1000 trays/hour (adjustable speed)

- Seeding accuracy: >97–98%

- Control system: Photoelectric sensing detection + PLC automatic control

- Drive method: Electric + Pneumatic

- Material: acero inoxidable

- Power: 500W

- Suitable Seeds: 0.3–12mm

- Suitable trays: 600×400mm (96-cell / 160-cell), tray width ≤550mm

The equipment has undergone comprehensive commissioning, trial operation testing, and cleaning/packaging. It has been shipped to Ukraine via logistics. We will concurrently provide operational training, installation guidance, and after-sales support to ensure rapid production deployment and stable operation, helping customers enhance seedling cultivation efficiency and quality.