Vegetable Seedlings Crawler Type Transplanter Machine For Sale

With its tracked chassis and multi-row design, the crawler type transplanter can easily cope with complex terrain, improve transplanting efficiency, and reduce labor intensity.

The crawler type transplanter machine is suitable for transplanting a wide range of vegetable seedlings, and is especially good at transplanting small seedlings such as onions.

Compared with the traditional wheeled transplanter, the tracked design can adapt to different terrains and complex ground conditions, ensuring smooth and stable operation.

The machine supports a 1-12 row multi-row operation mode, which greatly improves transplanting efficiency, reduces labor intensity, and effectively helps large-scale and mechanized agricultural production.

Core advantages of crawler transplanter

- Widely applicable: suitable for onion, kale, pepper, tomato, seedling cabbage, broccoli and other vegetable seedlings transplanting needs.

- Crawler chassis design: good terrain adaptability, suitable for plains, hills, wetlands and other complex conditions, walking smoothly, strong passability.

- Flexible multi-row operation: support 1, 2, 4, 6, 8, 10, 12 rows transplanting operation, to meet the needs of different planting scale.

- Efficient and accurate transplanting: fast transplanting speed and accurate planting spacing, significantly improving operational efficiency and survival rate.

- Reduced labor intensity: automated mechanical operation reduces labor input and saves labor costs.

Crawler seedling transplanter cultivation conditions

It can work normally when the absolute water content of soil is 15%~25%.

Exceeding the applicable range may lead to a decline in operating performance and shorten the machine’s service life.

When the machine works on the ridge, it is necessary to consider whether the distance and width of the ridge allow the machine to walk.

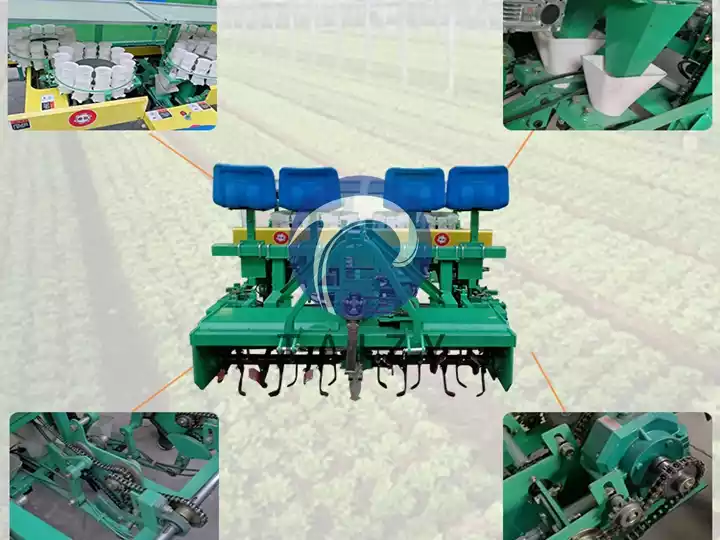

Structure of crawler transplanting machine

The crawler type transplanter machine mainly comprises a crawler walking device, engine, gear mechanism, frame assembly, duckbill hanging cup planting mechanism, lateral seedling casting device, and so on.

As shown in the figure:

- Crawler walking device: the crawler walking device is the device that drives the machine to move after receiving the power transmitted by the engine and the speed change system.

- Frame assembly: the frame is a door-type frame, and the machine plays a role in connecting and fixing it.

- Duckbill planting mechanism: the principle of crank arm linkage is the reciprocating action of the duckbill to complete the transplanting operation.

Crawler type transplanter machine working principle

- 2ZBLZ series self-propelled crawler type transplanter has various functions such as automatic traveling, lateral seedling dropping, and planting. The machine is powered by a small gasoline engine, which is highly efficient and energy-saving.

- The engine power acts on the walking mechanism, seedling throwing mechanism, and duckbill cup planting mechanism, realizing the mutual coordinated movement between different mechanisms.

- The power generated by the engine is transmitted to the travel drive shaft through the gearbox, which drives the driving wheels and tracks to realize the walking of the machine.

- Users can use different gears of the transmission to achieve different traveling speeds according to their needs, to adapt to the requirements of plot transfer and different seedling planting operations on the traveling speed.

- Replacing the adjusting sprocket of the planting drive mechanism with different numbers of teeth can adjust the planting distance of the crop and realize adjustable spacing to meet the planting needs of different crops.

- Seedling placement adopts a lateral seedling placement device, which ensures that the operator has enough time to place seedlings and effectively reduces the transplanting leakage rate.

Technical parameters of crawler transplanting machine

From the data below, you can see that we have a variety of crawler type transplanter models to choose from, and at the same time, we accept customization. We make the perfect machine to help you use a product that fits your business! If you have any questions, please feel free to contact us for more information!

| Model | Weight (kg) | Structure | Planting tool | Plant space(cm) | Row space (cm) | Height of seedling(cm) | Rows | Operator | Power(kW) |

| 2ZBLZ-4A | 450 | Self-propelled | The duck mouth hanging cup | 8-20 | 25-40 | 10-20 | 4 | 3 | 7.5 |

| 2ZBLZ-6 | 1050 | Self-propelled crawler | The duck mouth hanging cup | 8-20 | 15-20 | 10-20 | 6 | 4 | 7.5 |

| 2ZBLZ-8 | 1150 | Self-propelled crawler | The duck mouth hanging cup | 8-20 | 10-20 | 10-20 | 8 | 5 | 7.5 |

| 2ZBLZ-10 | 1250 | Self-propelled crawler | The duck mouth hanging cup | 8-20 | 15 | 10-20 | 10 | 6 | 7.5 |

| 2ZBLZ-12 | 1350 | Self-propelled crawler | The duck mouth hanging cup | 8-20 | 10-15 | 10-20 | 12 | 7 | 7.5 |

Methods of adjustment

Adjustment of transplanting depth

The crawler type transplanter machine in the field or the head of the field idle trial run, close the transplanting clutch to observe the upper and lower vertical position of the duckbill work to meet the transplanting depth requirements.

If the depth is not enough to adjust the transplanting mechanism above the adjusting screw so that the transplanting mechanism as a whole down to meet the use of the requirements, and vice versa if the transplanting depth is too deep.

Adjustment of transplanting spacing

According to the agronomic requirements, use the corresponding sprocket to replace the spacing adjustment sprocket.

Selection of transplanting machine operating speed

The principle of selecting the operating speed is to meet the agronomic requirements of transplanting, not only to ensure the quality of work but also to give full play to the rated power of the engine. The following are the traveling speeds corresponding to each gear of the crawler type transplanter.

| Gear | Speed |

| 1st gear | 0.8 km/h |

| 2nd gear | 1.34 km/h |

| 3rd gear | 2.1 km/h |

| Reverse | 0.66 km/h |

Our factory also produces wheeled self-propelled transplanters and tractor-driven transplanters. You can choose and customize the machine according to your planting scenario and seedling type. Welcome to contact us for more detailed information and machine quotation.