Customized 4-row Cucumber Transplanter for Swiss Client

Our factory has finished producing a wheeled self-propelled 4-row cucumber transplanter and has successfully shipped it to Switzerland. This customer is an agricultural business that specializes in cucumber cultivation and aims to enhance the precision of transplanting and the growing space for cucumber seedlings by acquiring our transplanter, ultimately achieving higher yields and better quality.

Customer needs and expectations

When selecting a transplanting machine, the customer had specific demands regarding the precision and efficiency of the equipment. After multiple discussions with our technical team, the customer inquired in detail about the spacing adjustments and ultimately decided on a configuration featuring 28 cm row spacing and 10-45 cm plant spacing tailored to their planting requirements.

The customer anticipates that this customized transplanter will accurately manage the spacing of the cucumber seedlings and enhance the growing area, ensuring that each cucumber plant gets enough nutrients and sunlight to support healthy crop growth.

Cucumber transplanter details & customization

This wheeled, self-propelled 4-row transplanter is engineered to enhance transplanting accuracy with precise adjustments for plant spacing. Key features of the machine include:

- Customers can select an adjustable spacing of 10-45 cm to provide optimal room for cucumber seedlings.

- The machine operates with 4 rows simultaneously, significantly boosting transplanting efficiency and minimizing manual labor.

- Its wheeled self-propelled design allows it to adapt to various terrains, ensuring smooth operation.

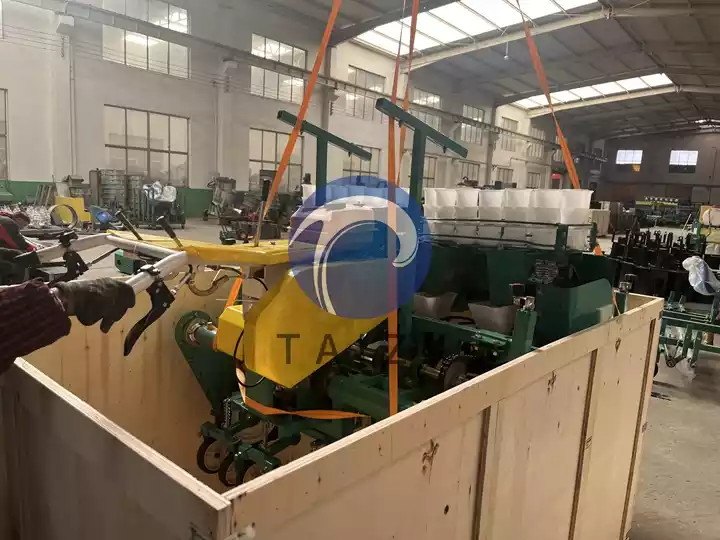

After the machine was built, tested, and approved by the customer, the loading and shipment went smoothly. The video below captures the loading process of the transplanter, highlighting the steps taken to ensure the equipment is transported safely:

This cooperation with Switzerland provides customers with a better solution in the cucumber planting process and reduces labor costs simultaneously. If you need, please feel free to contact us.