KMR-100 Fully Automatic Nursery Seedling Machine Shipped to Ukraine

We have successfully delivered a PLC-controlled KMR-100 fully automatic nursery seedling machine with air compressor to a modern agricultural client in Ukraine. This customer specializes in greenhouse seedling cultivation for vegetables, flowers, and grain crops. As their planting scale continues to expand, they have set higher requirements for transplanting precision and automation levels.

Equipment features and technical advantages

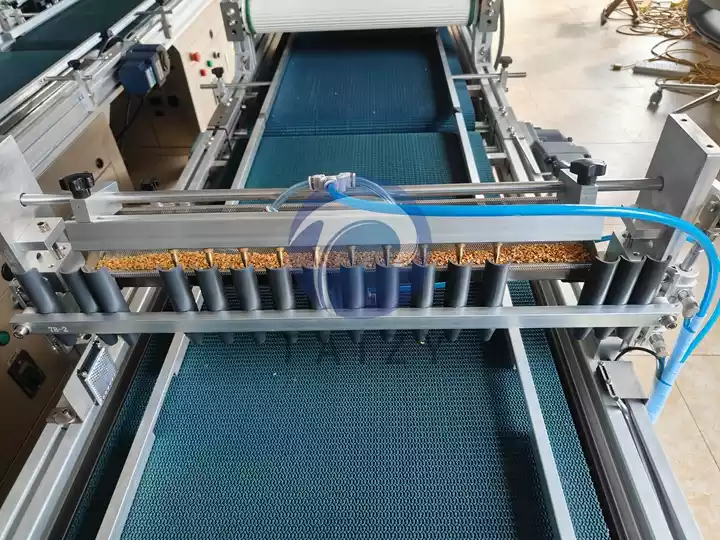

- The KMR-100 fully automatic seedling machine employs a combined electric-pneumatic control principle. Equipped with a PLC automatic control system and photoelectric sensing detection, it achieves high-precision automatic seeding and soil covering operations with accuracy reaching 97%-98%.

- The machine processes 400 to 1000 seedling trays per hour, with adjustable speed to accommodate various seed types and sizes (0.3-12mm).

- Constructed from stainless steel for durability, it accommodates standard 600×400mm trays (96-hole or 160-hole configurations) and multiple tray specifications.

- With a low power consumption of just 500W, this energy-efficient machine is an ideal choice for mechanized, intelligent production in medium-to-large-scale seedling centers.

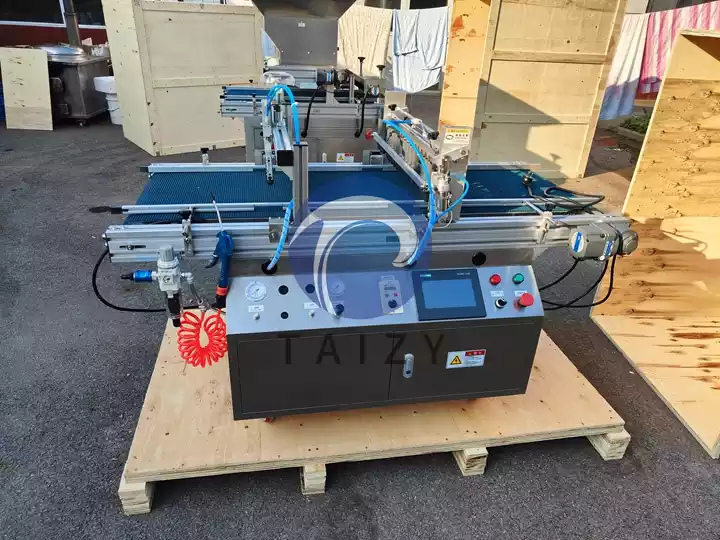

Shipping site of nursery seedling machine

Prior to shipment, our technical team conducted rigorous debugging and functional testing to ensure seamless operation and precise seeding across all components.

Staff then professionally packaged and reinforced the equipment using moisture-proof and shock-absorbing materials to guarantee safe delivery over long distances. The shipping site operated with orderly efficiency as workers carefully handled and verified equipment lists, with machines fully prepared for dispatch—demonstrating our company’s professional inventory management and logistics capabilities.

The client expressed great anticipation for the equipment to arrive and be put into use as soon as possible. They are confident that the high efficiency of this fully automatic seedling grower will significantly enhance seedling production speed and quality, reduce labor costs, and drive the automation upgrade of local agricultural production.